Rotary Table Automatic Packing Line

Description

Rotary table automatic packing line, consisting of a round table automatic distributor, a transition conveyor, an aligning conveyor and the packaging machine, is mainly designed for product distribution, aligning and feeding by utilizing the centripetal principle. Its packing speed can automatically adjust according to the feeding speed.Working procedure of this auto rotary table packaging line: the round table automatic distributor feeds products, the servo motor at the aligning part controls the feeding speed, and then products go orderly and fast through convey belts of the transition conveyor and the aligning conveyor. When passing the aligning conveyor, the aligning and feeding speed of products will be adjusted so as to keep the same with the packing speed of packaging machine. Push block enables products to go to the packaging machine without stuck, and after film wrapping, the packaging finishes.

Feature

s

1. The rotary table automatic packing line can be directly connected to the production line to fulfill the needs of fully automatic mass packaging. Manually decanting products into the round table is also feasible to satisfy small-scale and versatile packing requirements. 2. Customized design on the basis of product features, avoid squeezing the packaging materials, and materials which stuck or failed when turning direction will be rejected to ensure a stable and constant packing process. 3. Speed of the auto rotary table packaging line can be adjusted through inverter and servo driver and based on customer request and forms of packing materials. 4. User-friendly design, allowing easy and fast assembly and disassembly. 5. Equipped with a wide variety of safe devices, including emergency stop, fault stop, electricity leakage protection, warning light, etc.Structure

of Rotary Table Automatic Packing Line

1. Round Table

A

utomatic

Distributor

The round table automatic distributor consists of one inner turntable, one outer turntable and the output part. These three parts are controlled by three motors. Two inverters control the speed of inner and outer round tables, making turning speed adjustable. This distributor is mainly used to automatically feed products.

2. Transition

Conveyor

The transition conveyor, with simple structure and adjustable belt width

as per different products, transits products to the aligning conveyor.

3. Aligning

Conveyor

The aligning conveyor aligns the coming products, including product store, aligning and feeding to ensure the

feeding speed consistent with the packing speed of the packaging machine.

The photocell

electrical eye that controls product storage as well as feeding speed and time assures continuous package, thus avoiding empty bag.

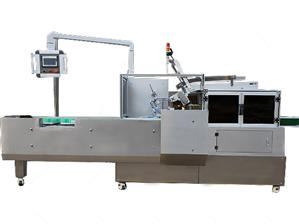

4. Packaging

Machine

The packaging machine is

available as per the packing items.

Parameter

s

of Rotary Table Automatic Packing Line

| Model | |

| Film Width | Max. 250 mm |

| Bag Length (mm) | 45 to 90 |

| Bag Width (mm) | 45 to 90 |

| Product Height | Max. 35 mm |

| Film Roll Diameter | Max. 320 mm |

| Packing Speed | 60 to 330 packs/min |

| Power | 220 V, 50/60 Hz, 2.4 kW |

| Machine Size (mm) | (L) 5520 × (w) 1350 × (H) 1520 |

| Machine Weight | 1200 kg |

Related packaging machines

-

- Fully Automatic Masks Carton Box Packing Machine Fully Automatic Mask Box Packing Machine is automatic high speed continuous packing machine which is high performance product incorporates p ...

-

- Automatic Surgical Mask/ N95 Masks Box Cartoning Packing Machine Machine will pick up box , send face mask into box, sealing the box , we can connected to the wrap machine for face mask making machine fo f ...

-

- High Speed FFP2/ KN95/ N95/ Surgical Mask Surgical Mask Packing Machine Suitable for pre-made pouch packaging of KN95, FFP2, N95, surgical masks, plane masks, medical masks, disposable masks etc. Suitable Pouches ...

-

- Automatic Surgical Mask Packaging Machine With Folding Ear Rope Machine Full automatic surgical mask packing machine with folding ear rope machine, It is suitable for packaging all kinds of flat mask earbands aft ...

-

- Automatic Surgical Mask/ KF94 Mask Bag Packing Machine Four-Sides Sealing This mask packing machine is suitable for four-sides sealing bag packing, such as various surgical mask, kf94 mask, medical masks, disposabl ...

-

- Full Automatic Flat Masks Packing Machine 25/ 50 Pcs Per bag Applicable for packing 10pcs/ 25pcs/ 50pcs flat masks, medical mask, disposable mask, protective glasses, etc. ...

-

- High Speed Face Mask Packing Machine Double-Channel 4 Side Sealing The four-side sealing mask packaging machine is suitable for single packaging of various disposable masks, medical masks, kf94 masks, N95 ma ...

-

- Automatic Face Mask Packing Machine High Speed High Speed KN95 mask packing machine is our company independent production design of a dedicated to kind of mask pack, servo control, length ...